*UPDATE: My heart goes out to everyone involved and I have no doubt in your skills and passion and that you will succeed wherever you set foot, I’m here for anything you need help with, my contact details are here.

*UPDATE2: Thank you everyone for your kind and encouraging words, I’m overwhelmed by the vast amount of support in these tough times.

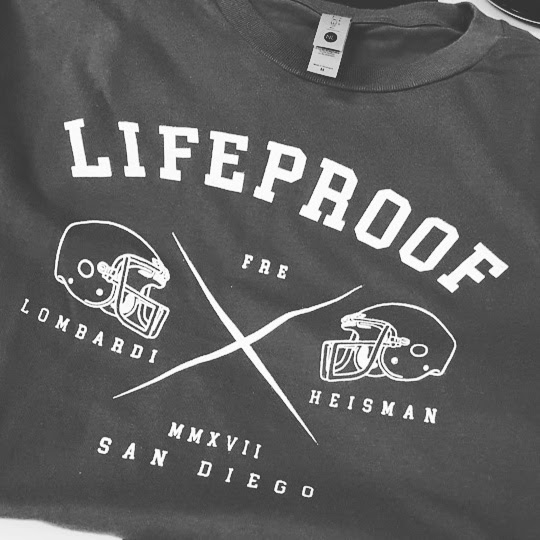

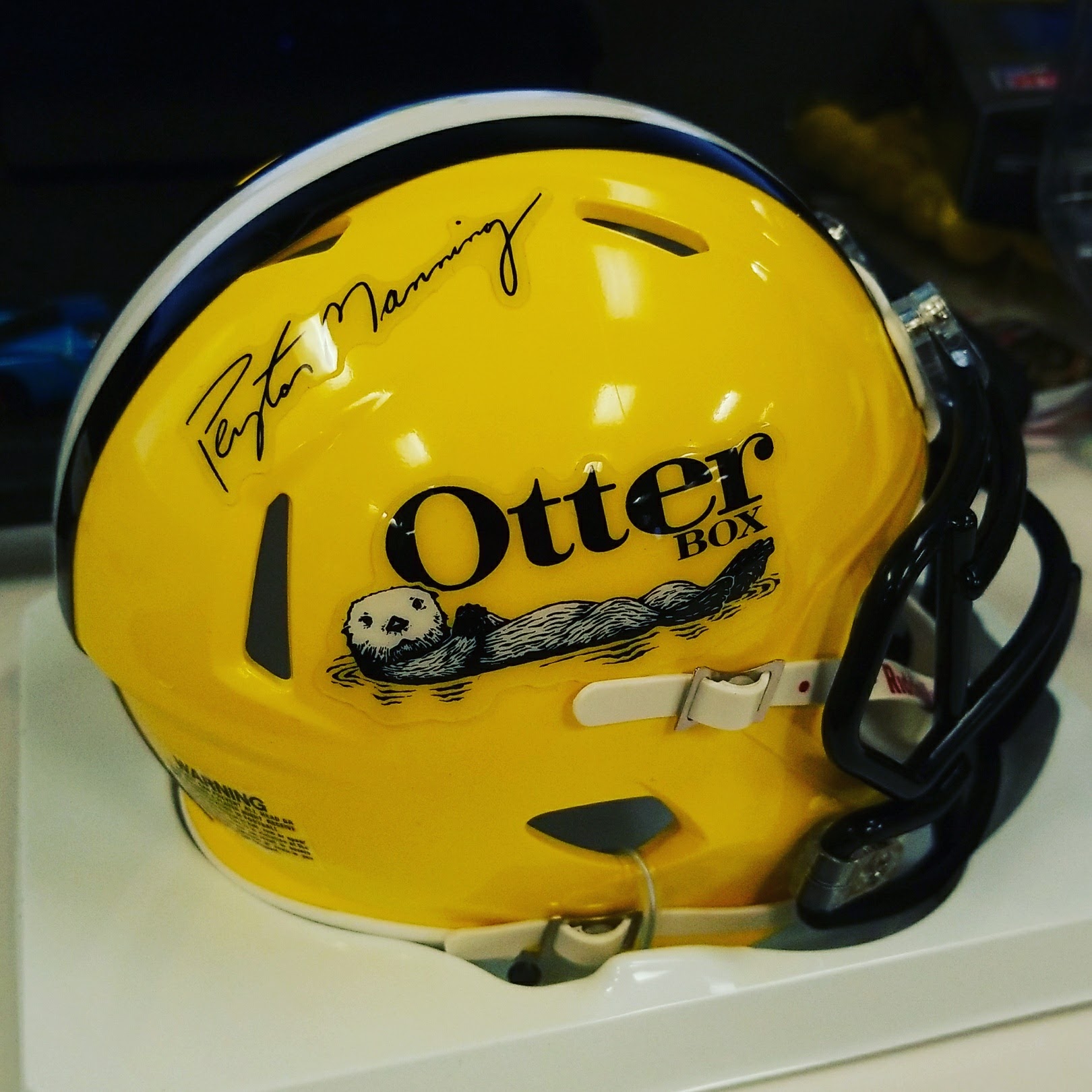

In this restructuring event, a lot of people were let go including the remote Mechanical Engineering force in San Diego, the OG brilliant minds from LifeProof, the ones that figured out, developed and delivered fully waterproof mobile device cases while allowing for full functionality, the LifeProof FRE case.

I’m a bit bitter, a bit sad, seeing my coworkers, my brothers in arms of many years, one by one announcing getting the dreaded email including myself, no explanation yet but we had it seen a mile away.

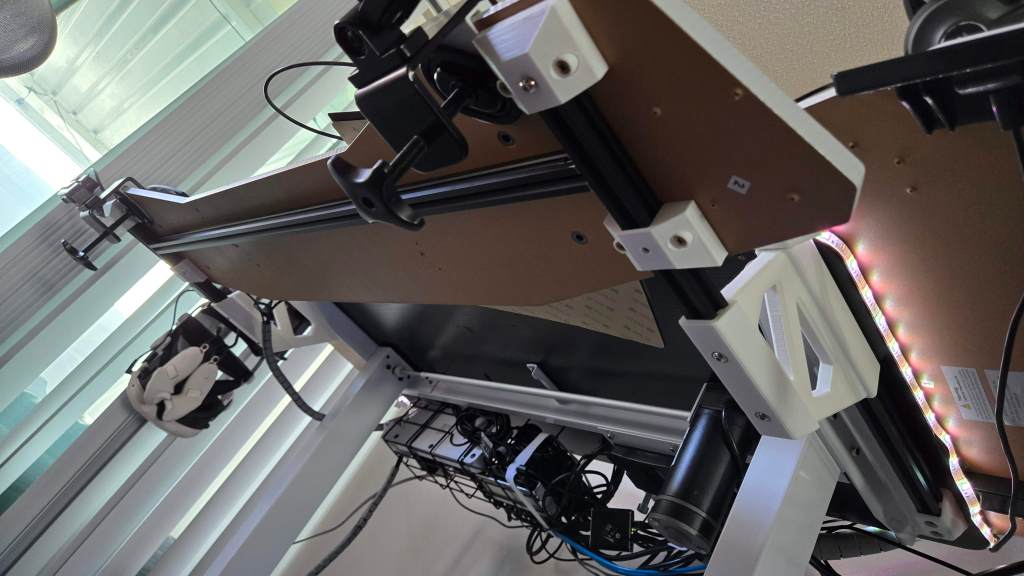

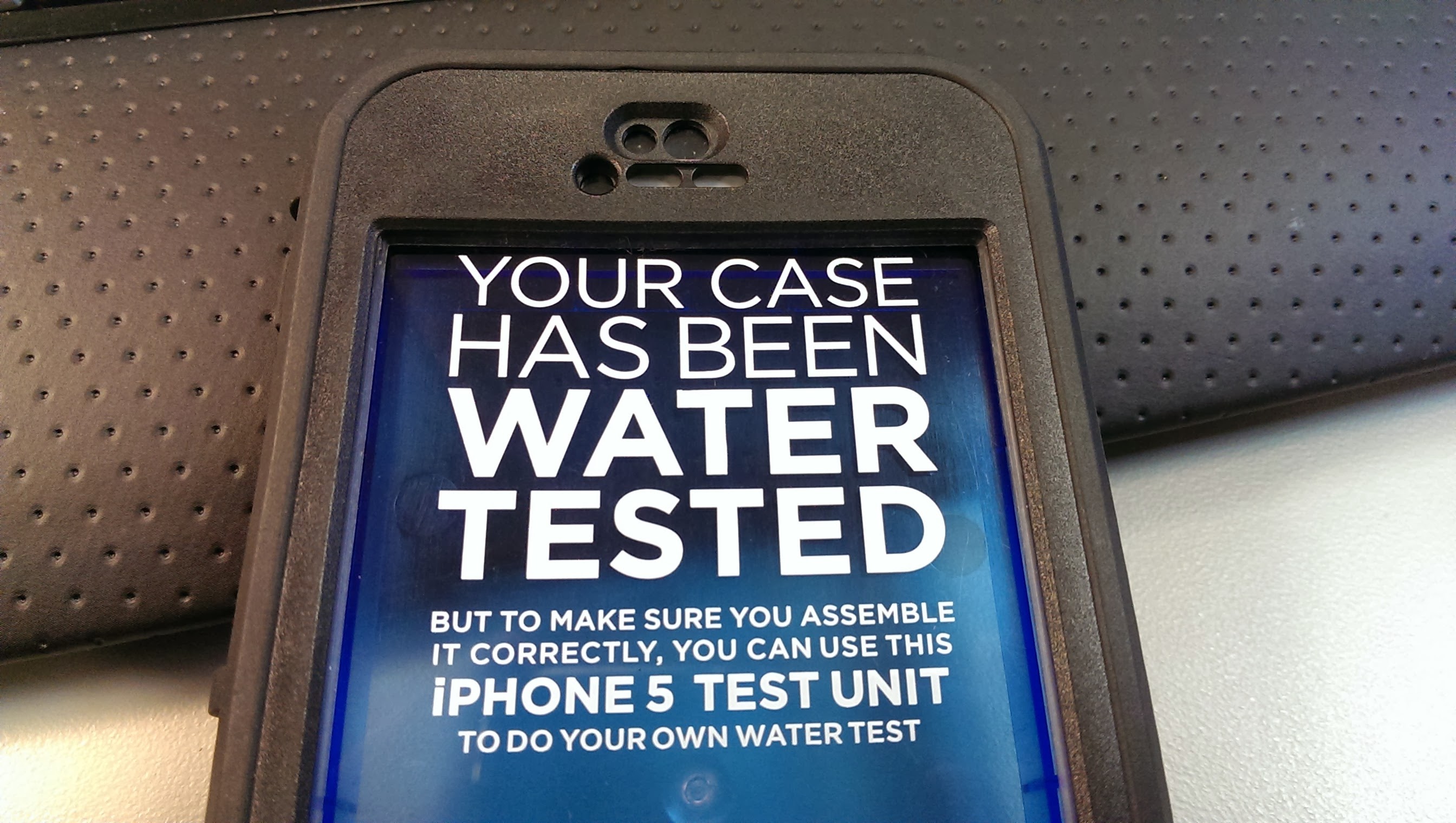

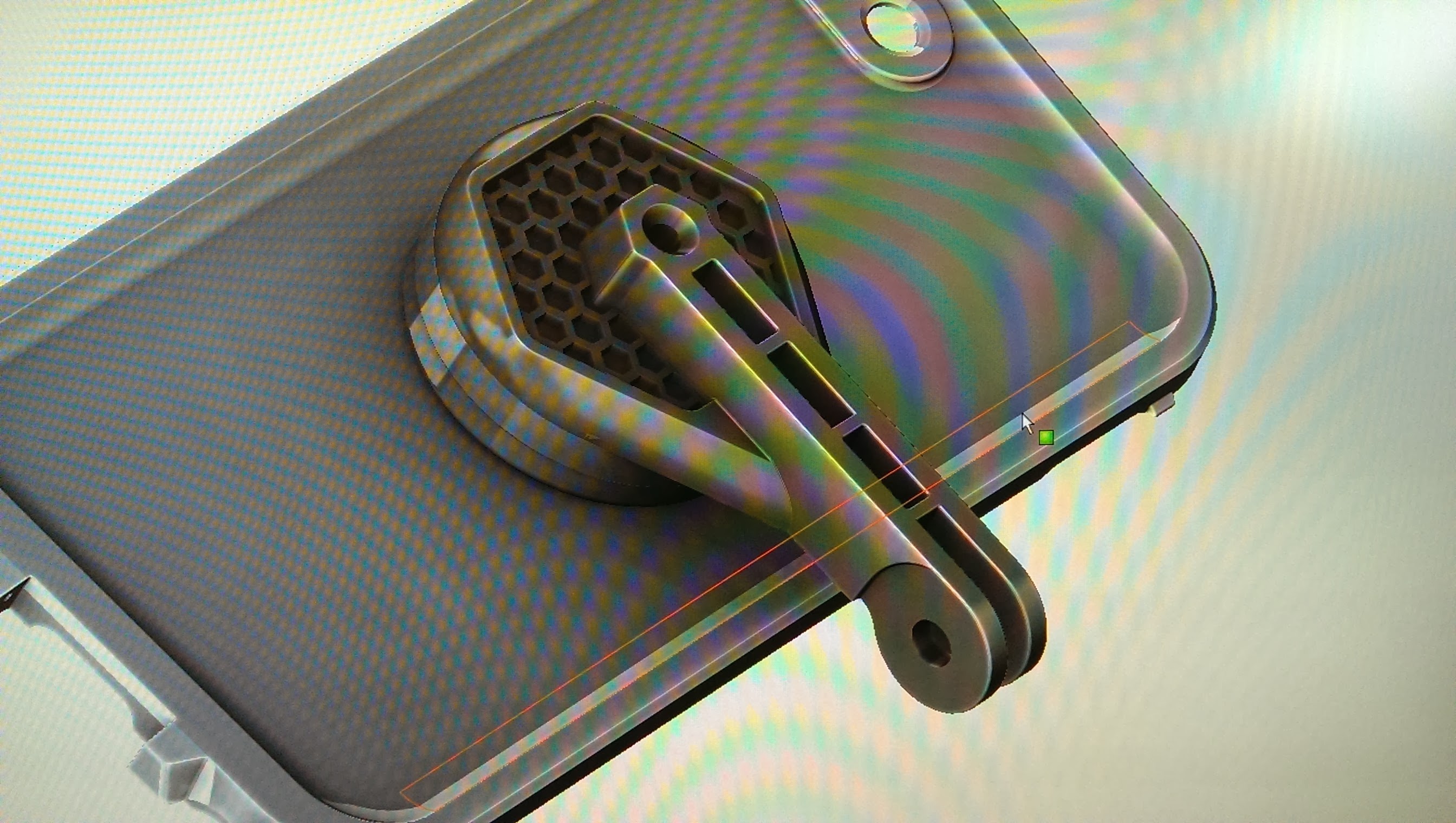

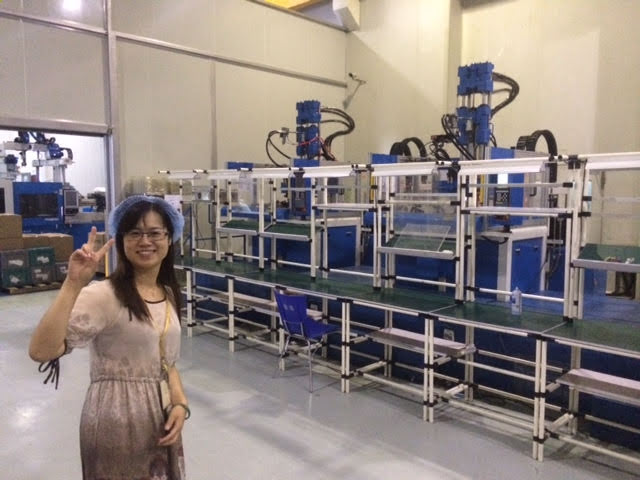

What makes FRE special? It’s just a waterproof case, why not use a Ziploc bag? Well, once you seal a phone device in a watertight enclosure, you need to worry about sound, about the microphones and how they interact with the software algorithms, the cameras with optically clear lenses and the flash that wants to bleed light wherever it can. And the touchscreen, it needs to seal out 100%, prevent it from creating those rainbow ring artifacts, reduce fingerprints, add scratch resistance, etc., the materials used are also tested for ultraviolet degradation, common solutions (think lotions, sunscreen, alcohol, etc.), button forces, latch retention… and, yeah, drops, the case should continue being waterproof after being dropped, all in a very sleek package that rivals drop protection only cases in size and style. Oh, and it has to be produced millions of times, assembled and tested, yes, each case is tested for water ingress before packaging.

Back to the situation, maybe it was a good thing, maybe it was time, there was no development career for my position and salary was capped for many years. But what if… what if that’s what I wanted to do, to continue the challenges of designing and developing for new series, new devices, maybe I wanted to continue for 10 more years. Maybe there is something else waiting and I needed a push, after all, I wouldn’t been here if it wasn’t for these life nudges.

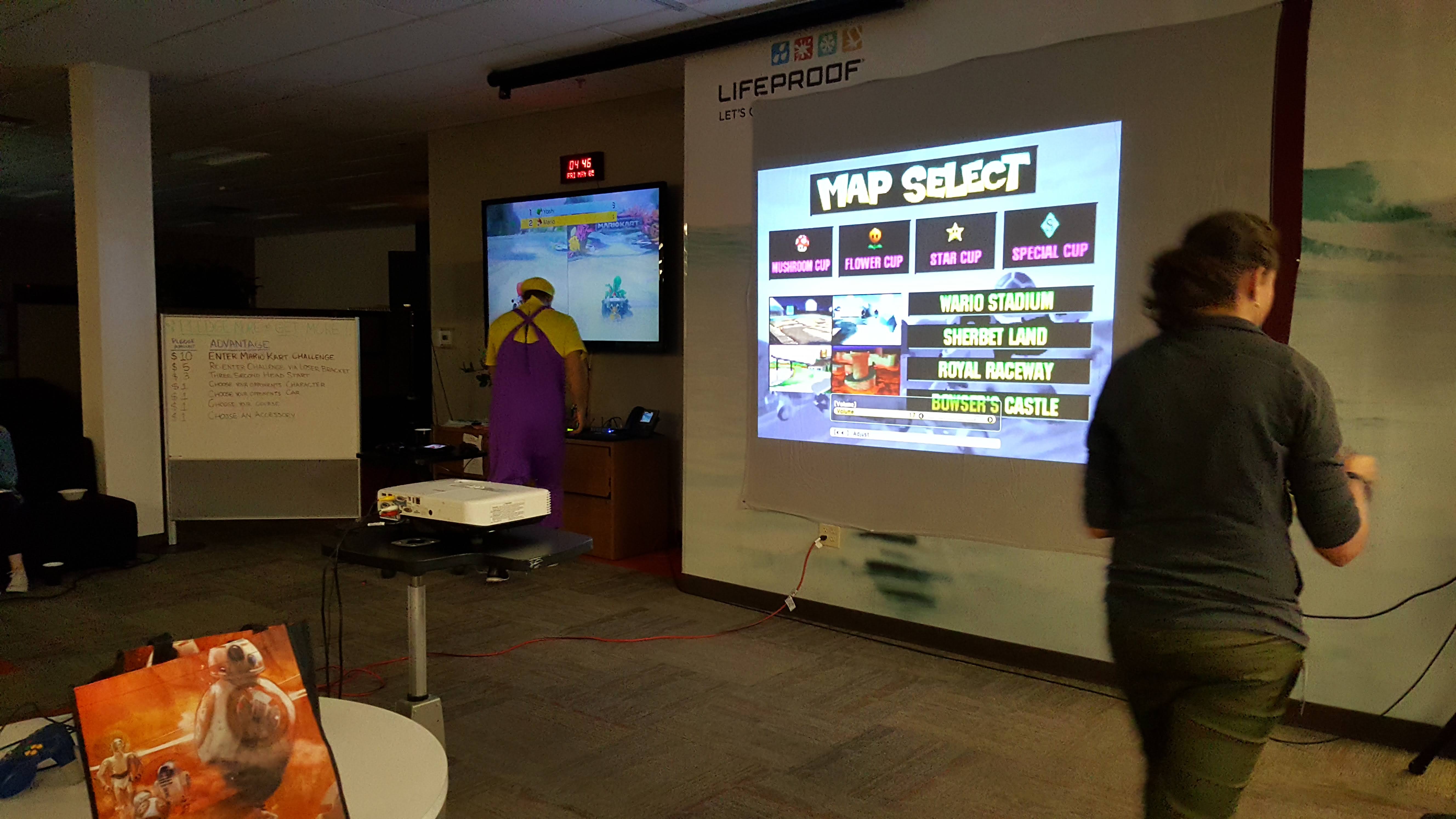

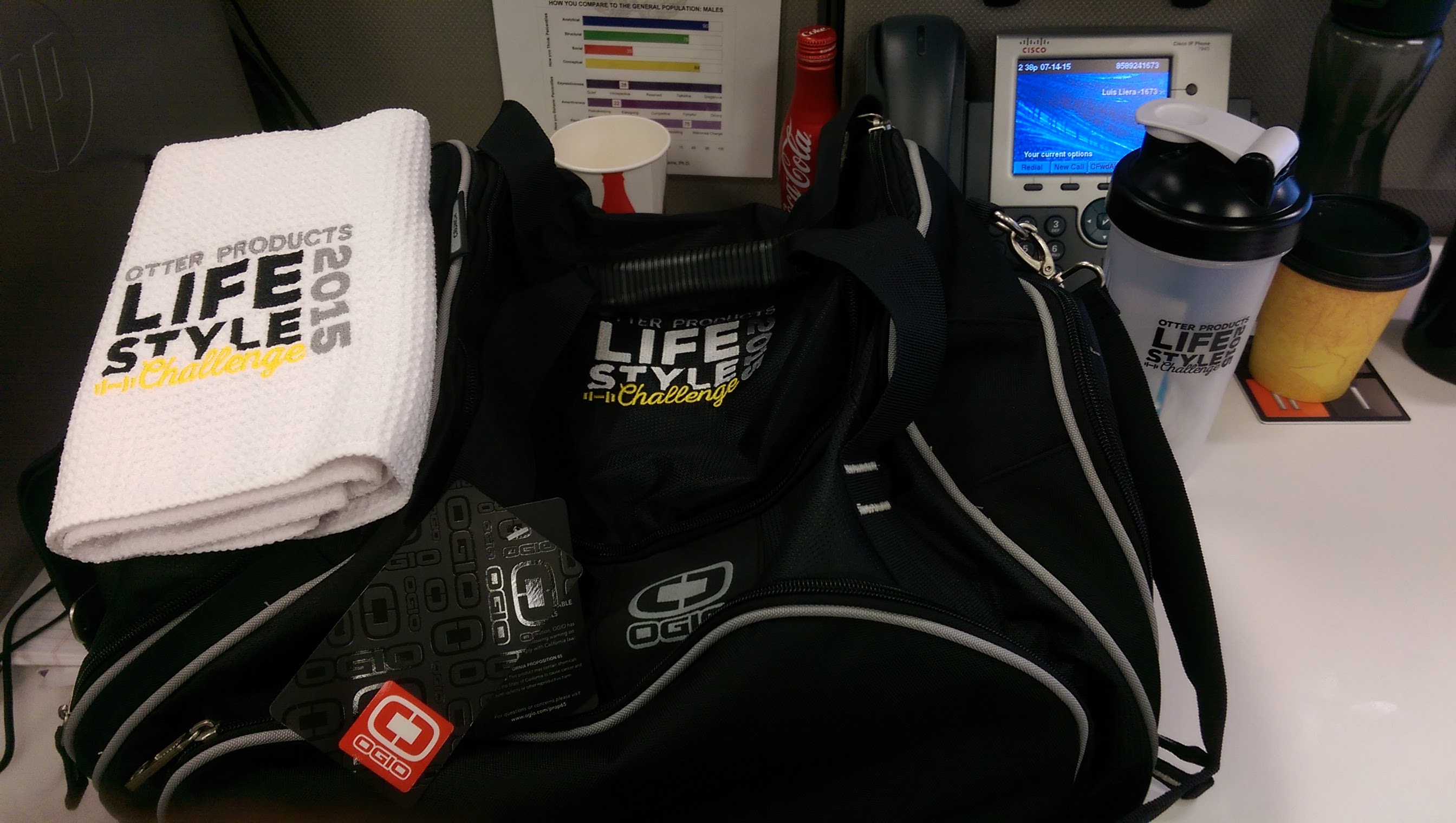

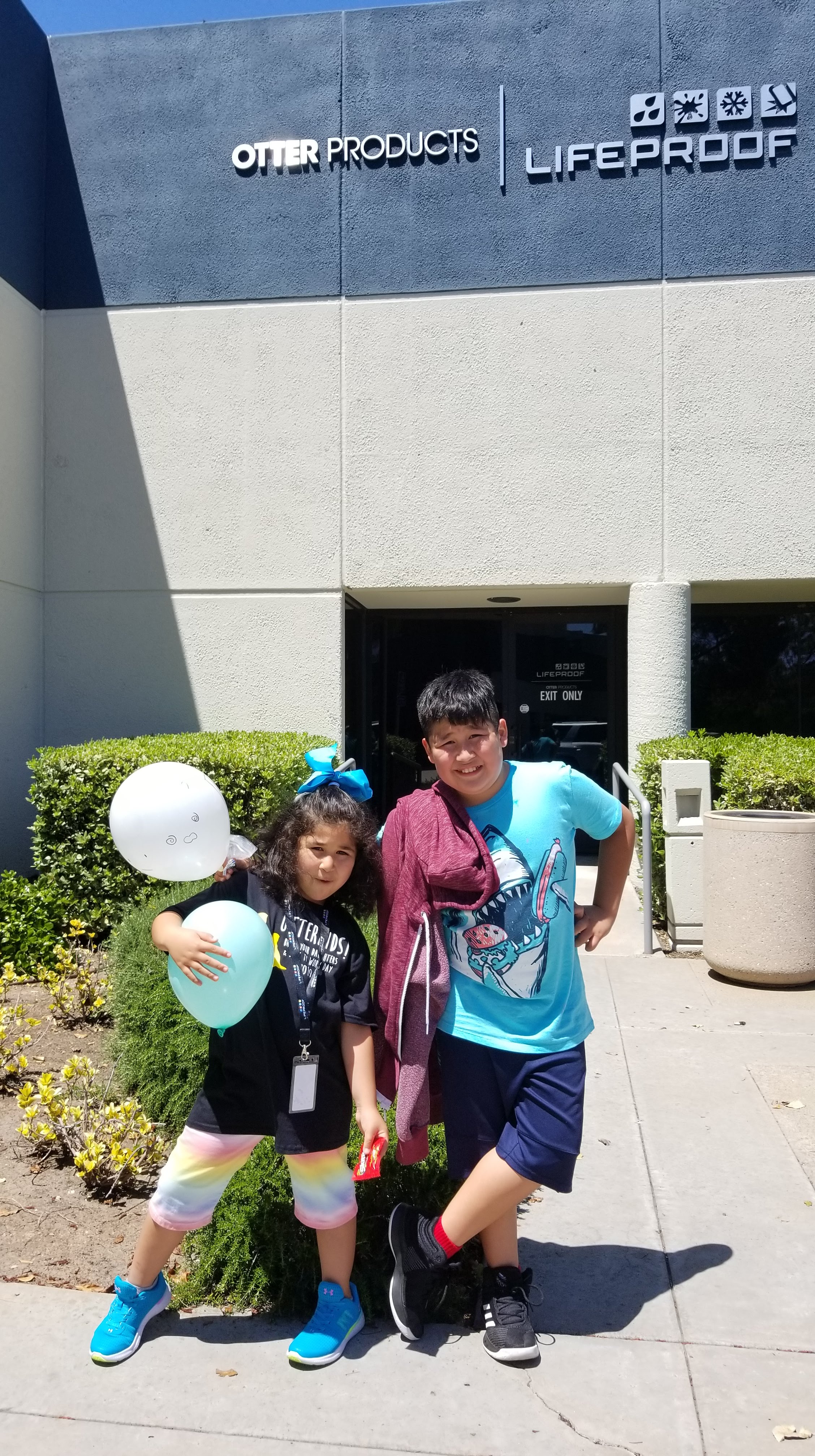

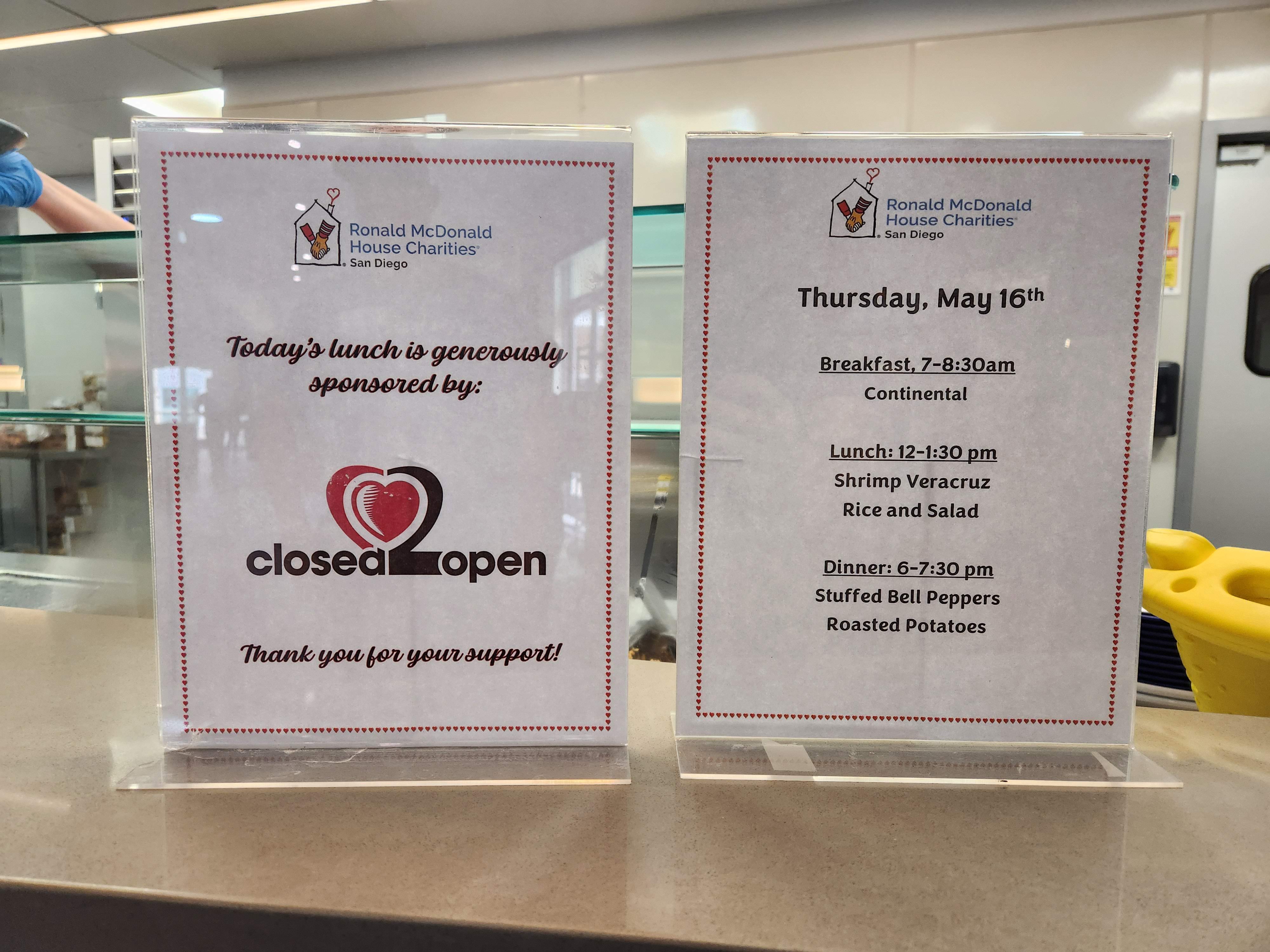

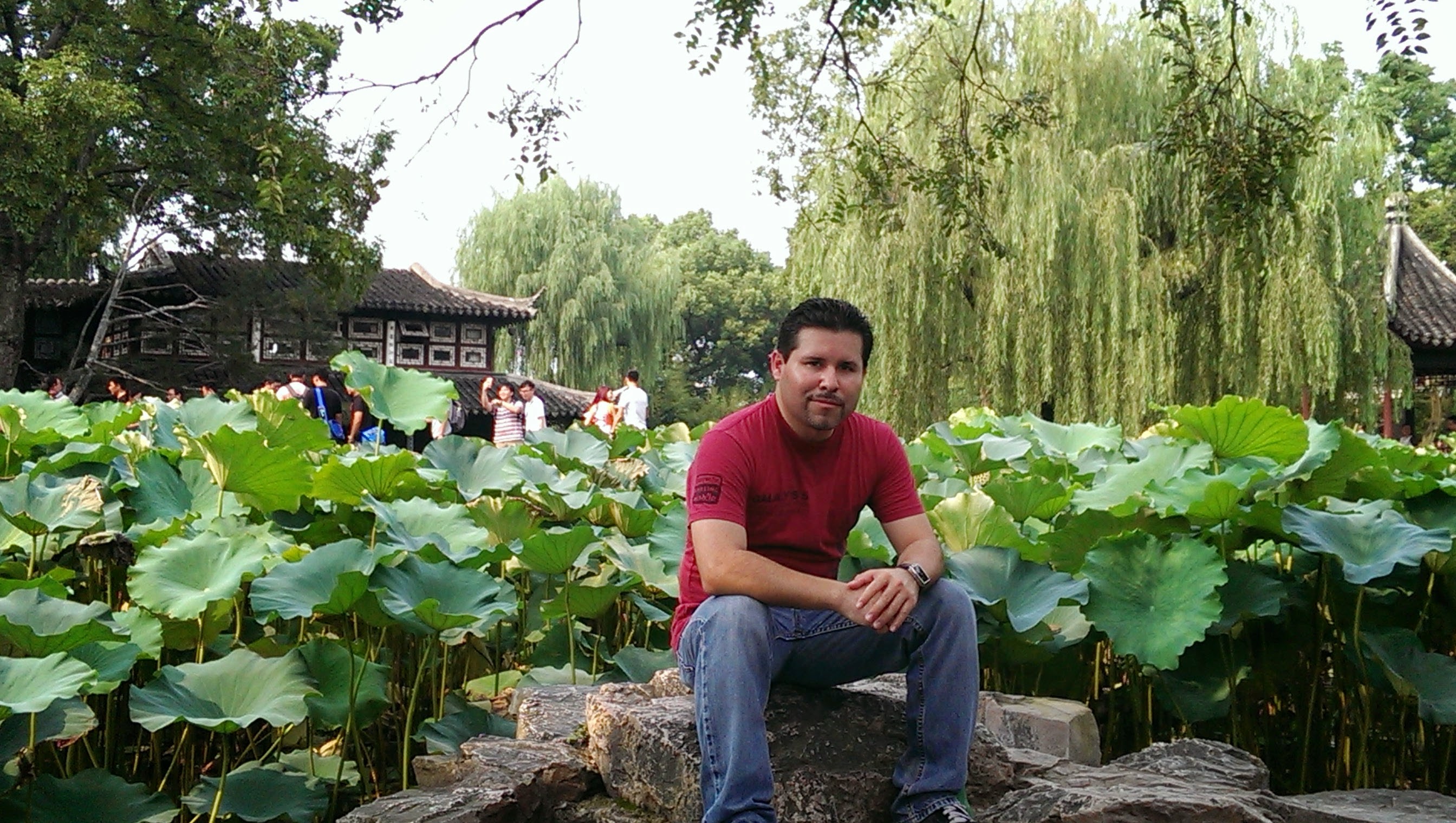

But oh well, after 11.5 years in the company seeing the evolution from LifeProof to OtterBox and everything in between, my daughter was born a few months before starting here, I’m very grateful to have had the opportunity to build, shape and implement a modeling infrastructure that helped reduce design time from months to weeks to days in some “cases”, the foundation has been baked-in across all case series templates and it’s amazing to see it develop and deploy way further by the team of awesome Mechanical Designers (YOU’RE NOT A CAD DESIGNER, YOU’RE A MECHANICAL DESIGNER, keep the fight on); I’m grateful for being part of the design and development of our most challenging product series, I’m grateful for the opportunity to visit OEM partners and factories across the sea, and out-of-state events; I’m grateful for all the ongoing learning and development that an environment like this provides; but above everything else, I’m grateful to have worked with the most amazing engineering minds here and in Fort Collins, seeing them “kick-ass” solving issues (features) that new devices constantly threw at us, and their growth across all these years, our managers who always put their peers before them and doing the best with what the company provided, and my mountain biking peers whose motivation sparked back my interest in the sport and adventure.

Thank you everyone.

So, what’s next?

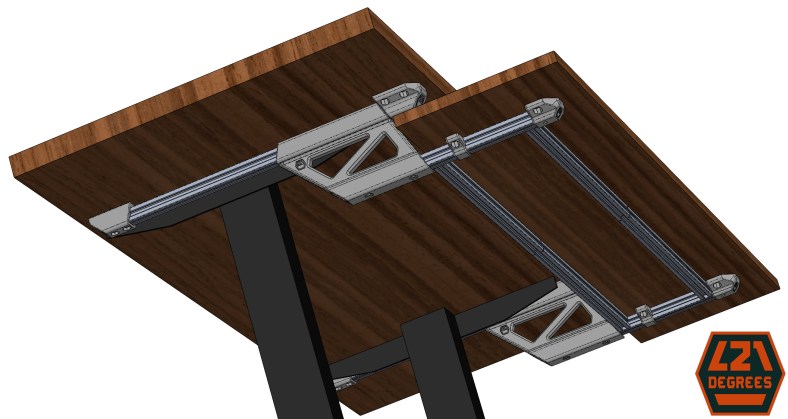

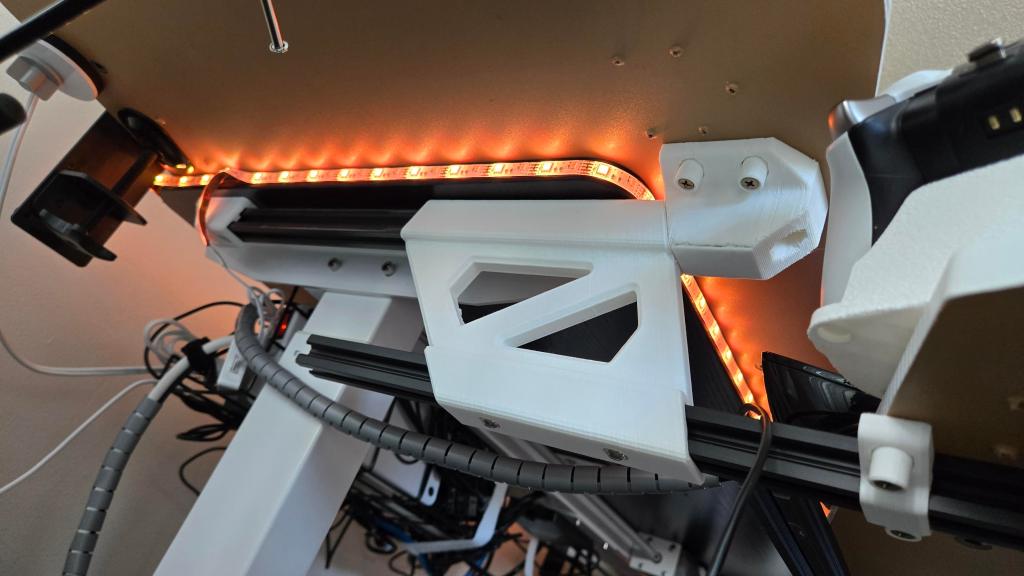

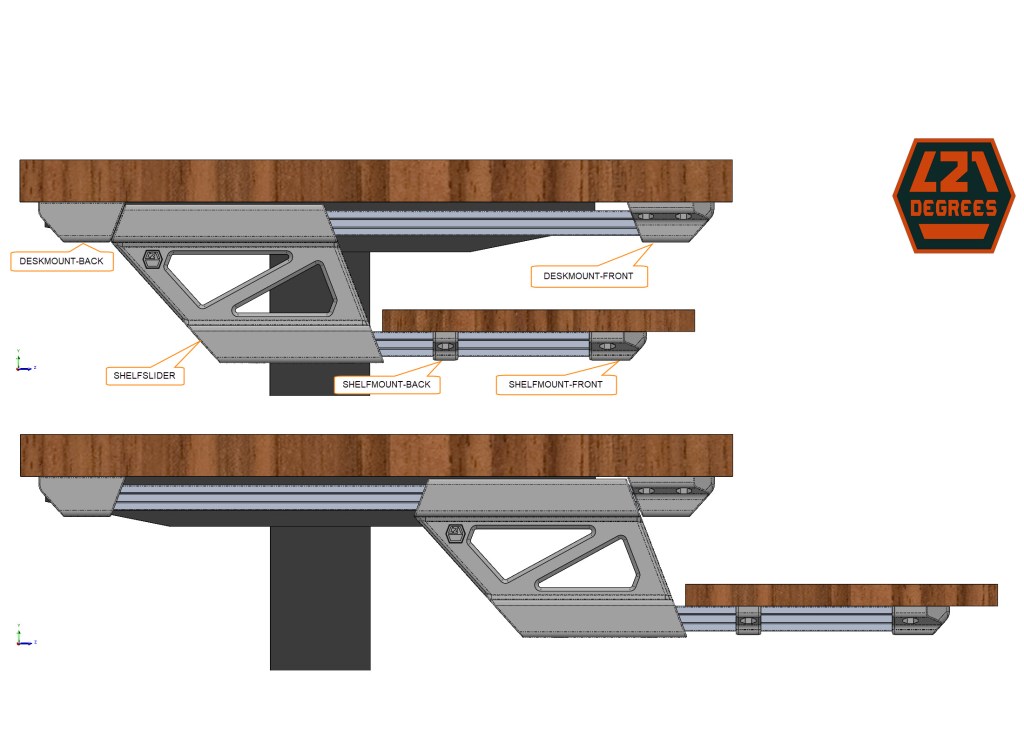

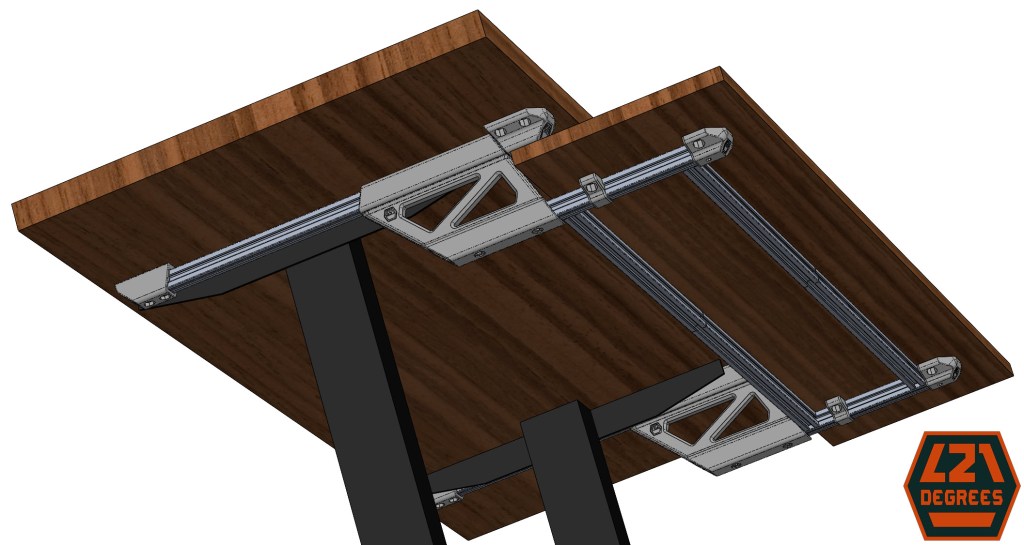

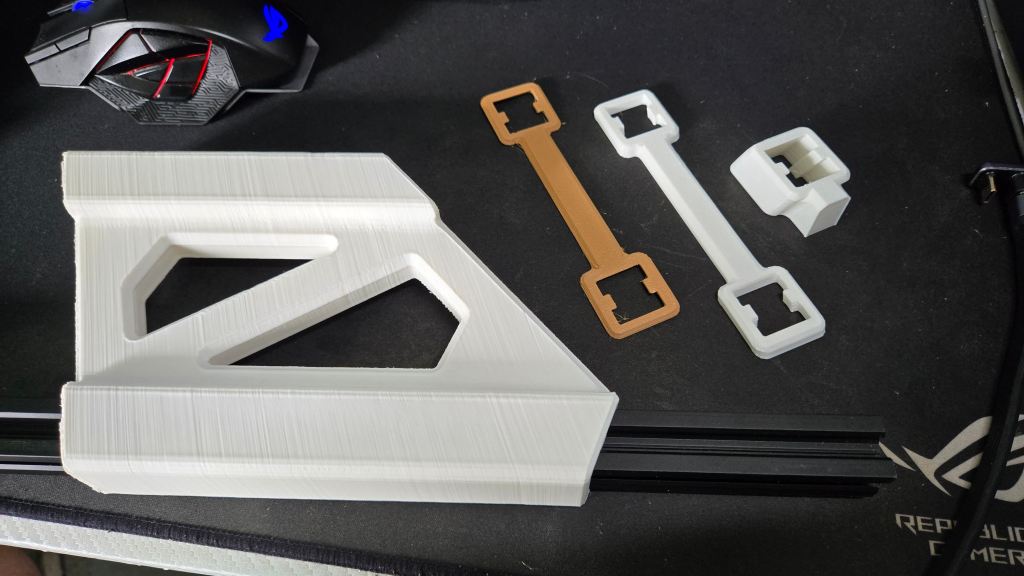

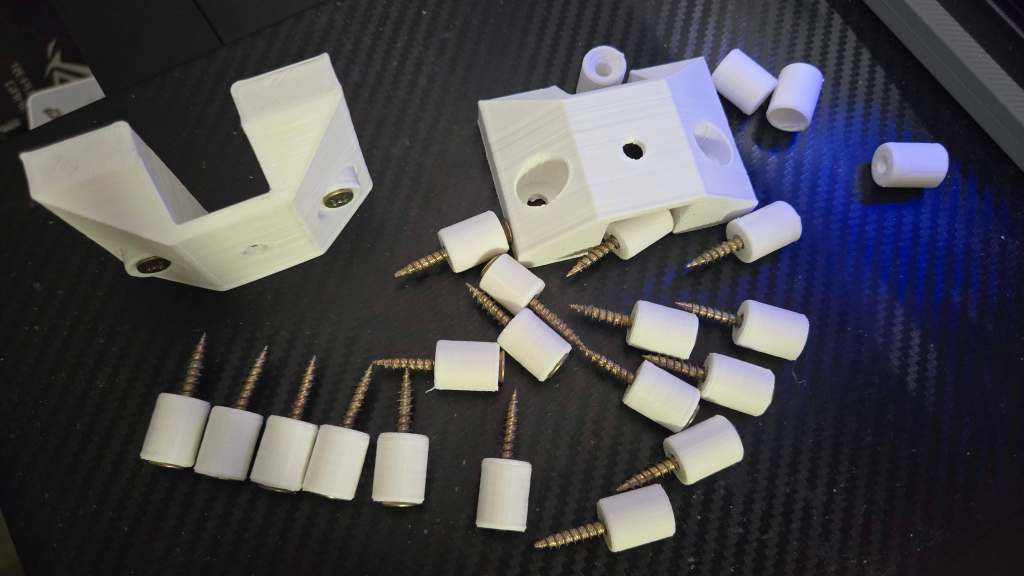

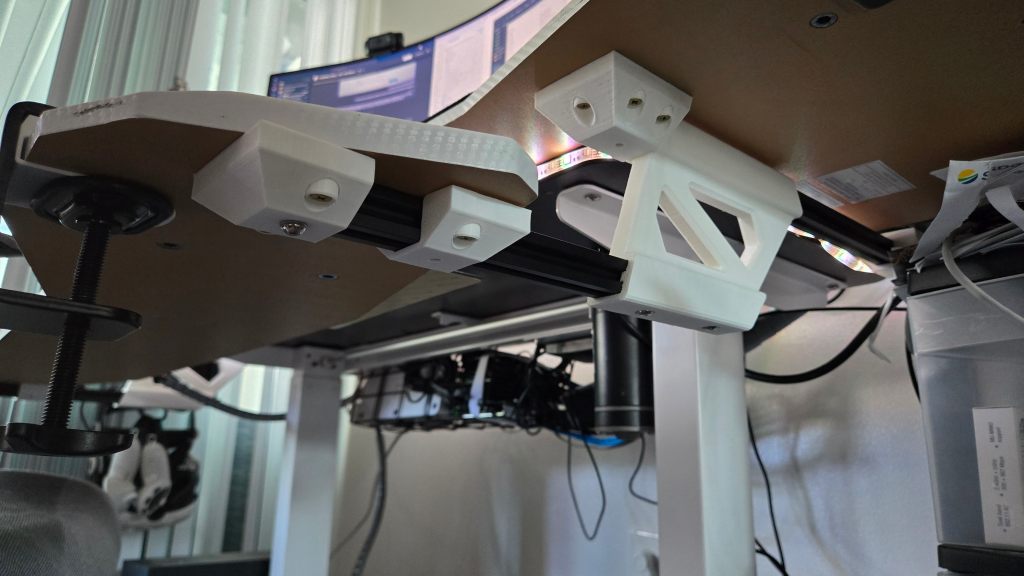

I have gone through elevator cab building and designing, shipboard furniture design, injection molding tooling design, then product design and development, I can say that I have enjoyed the last one the most but I’m not afraid of venturing into other areas, I’m very interested in additive manufacturing (ref this website), maybe design services? I can’t be too picky, I have a lifetime project to take care of which is my family, but I hope that the answer comes sooner rather than later.

Thank you for everything…

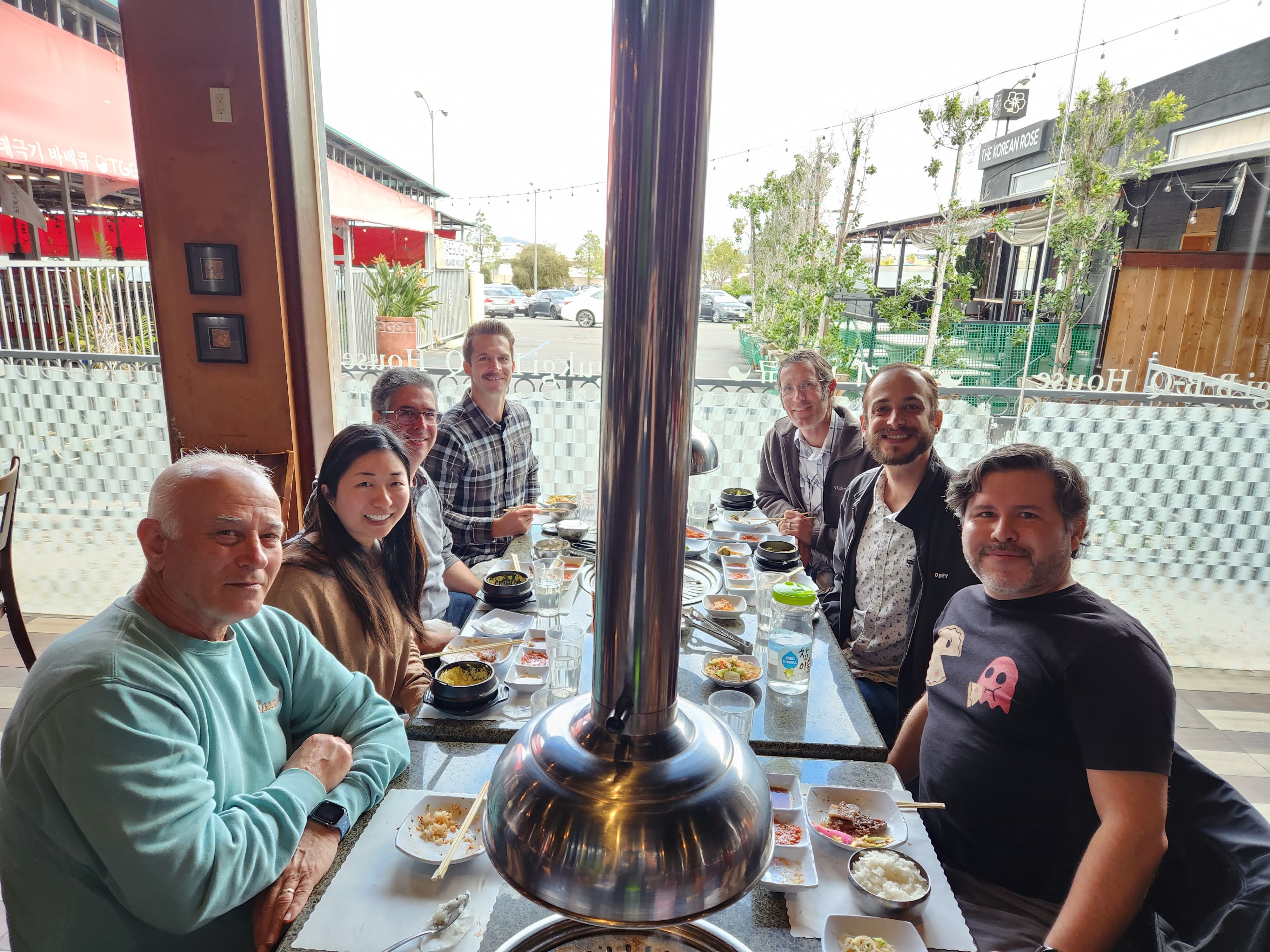

San Diego

Colorado

Suzhou

Suwon

Seattle

Charlotte Motor Speedway