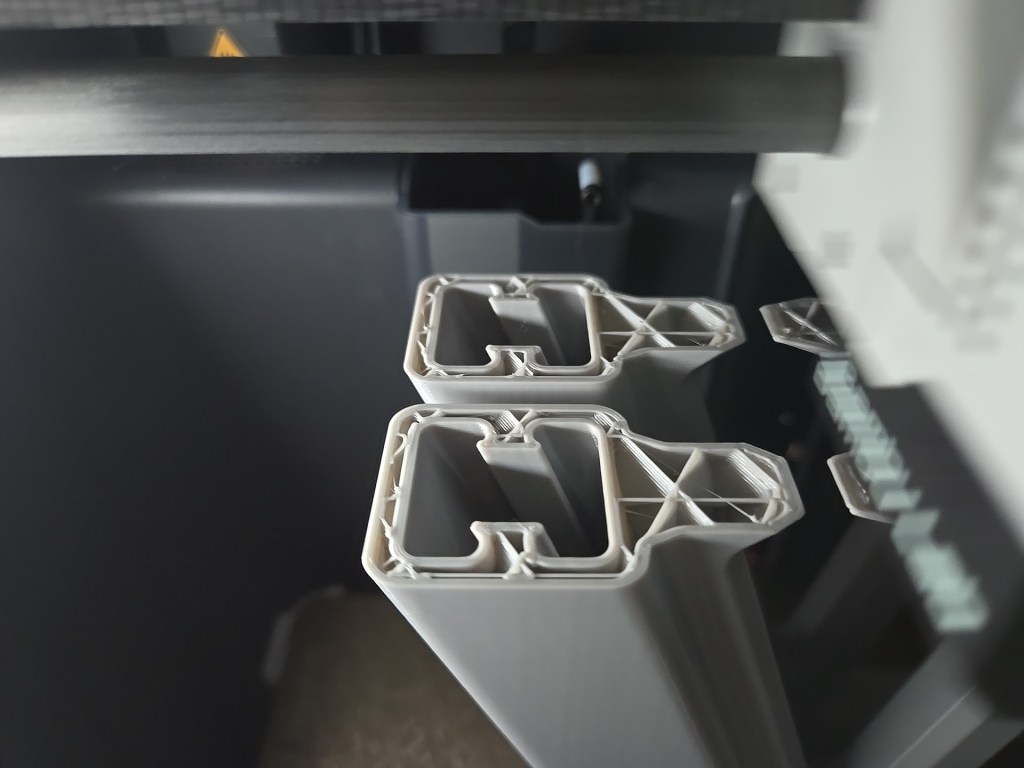

I decided to print my keyboard shelf parts on the P1S on PETG and gray color. But before that, I wanted to implement some changes to improve the mounting and sliding action.

Things I wanted to address in order of importance:

- Improve sliding action and allow for grease

- Use more standard screw length eliminating my custom spacers

- Use PETG instead of PLA since the latter started shaving against the aluminum

- Replace the ugly print quality of the older ones

- Another color (gray, also neutral but different from desktop)

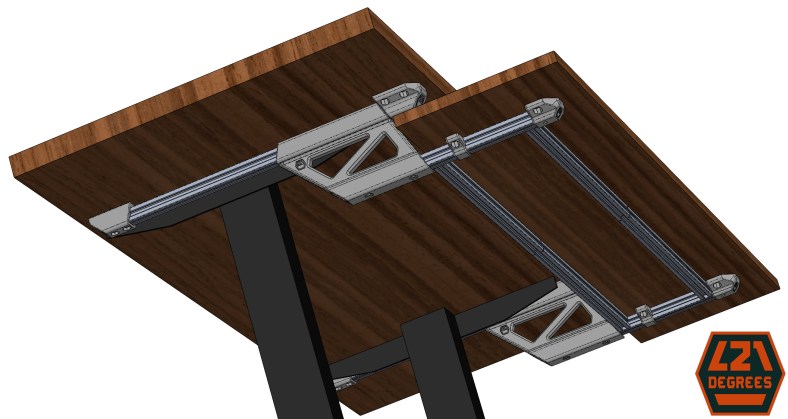

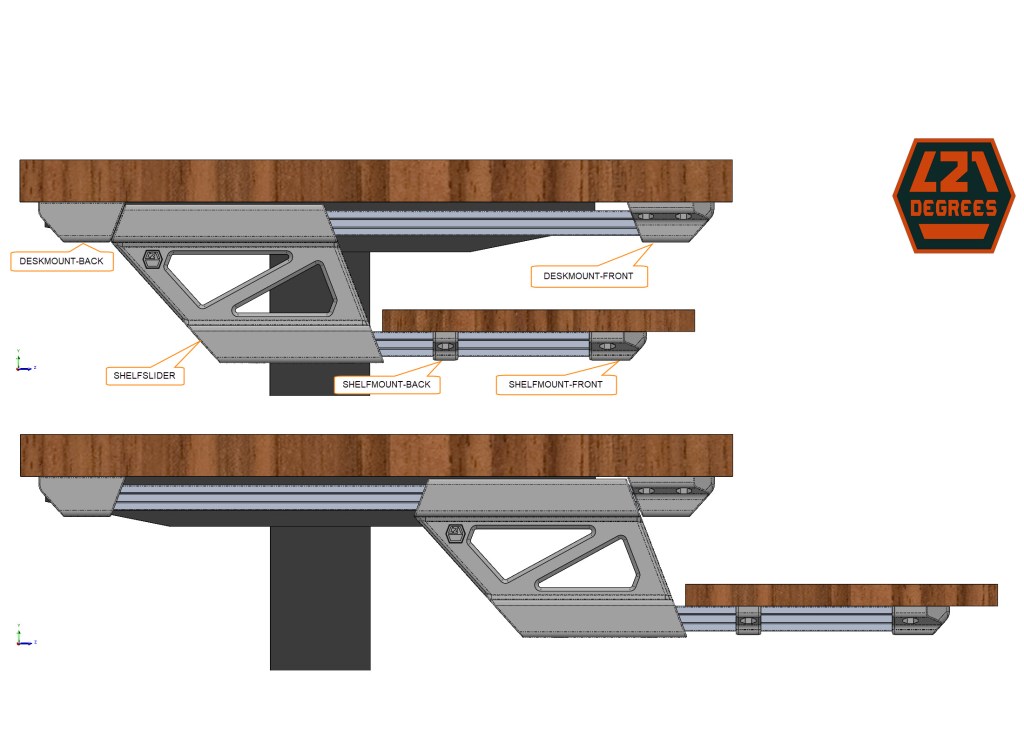

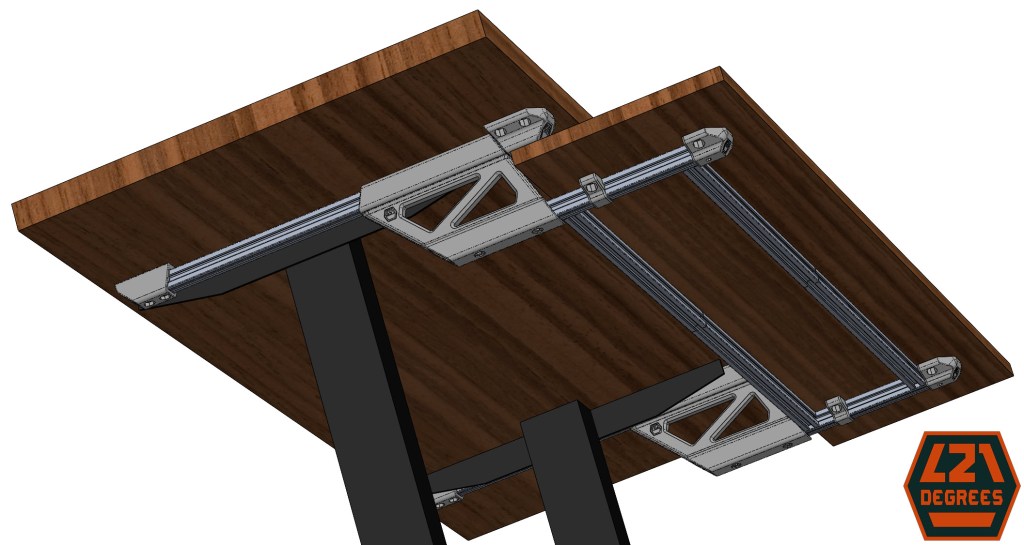

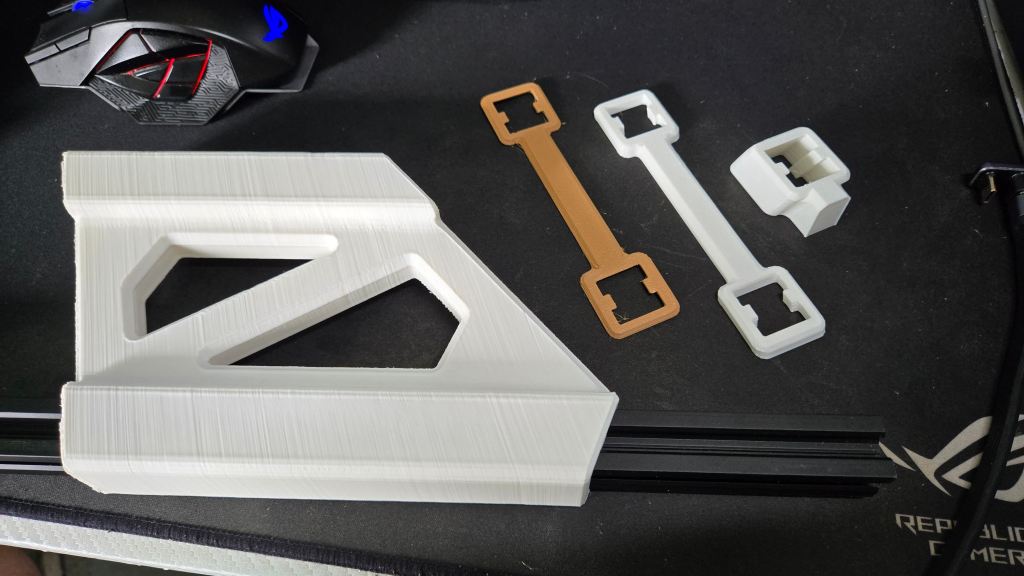

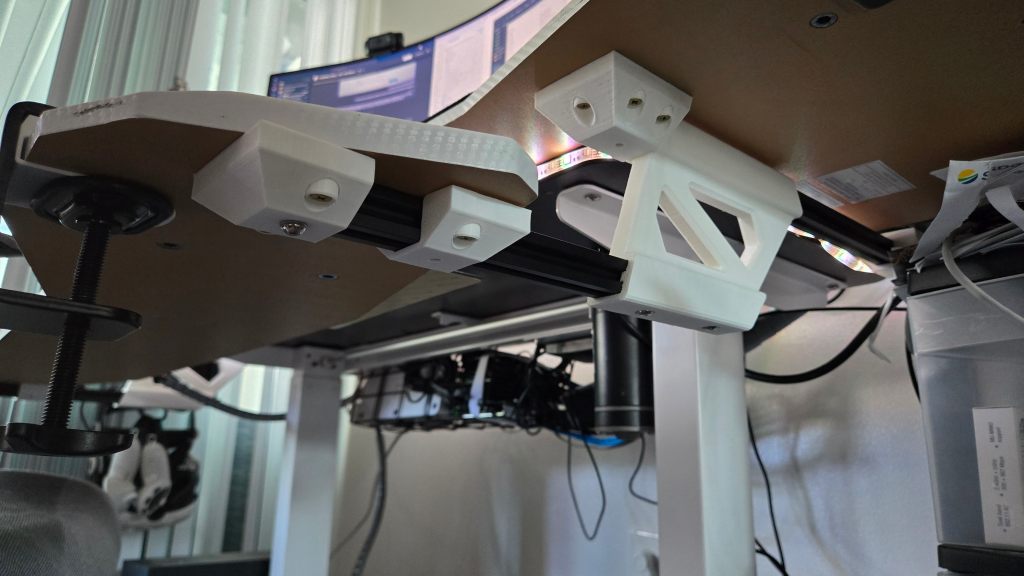

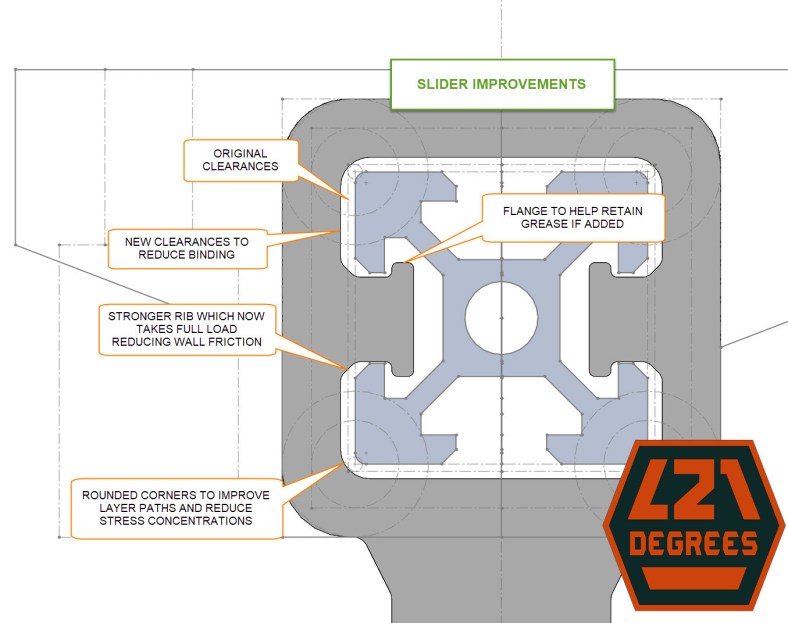

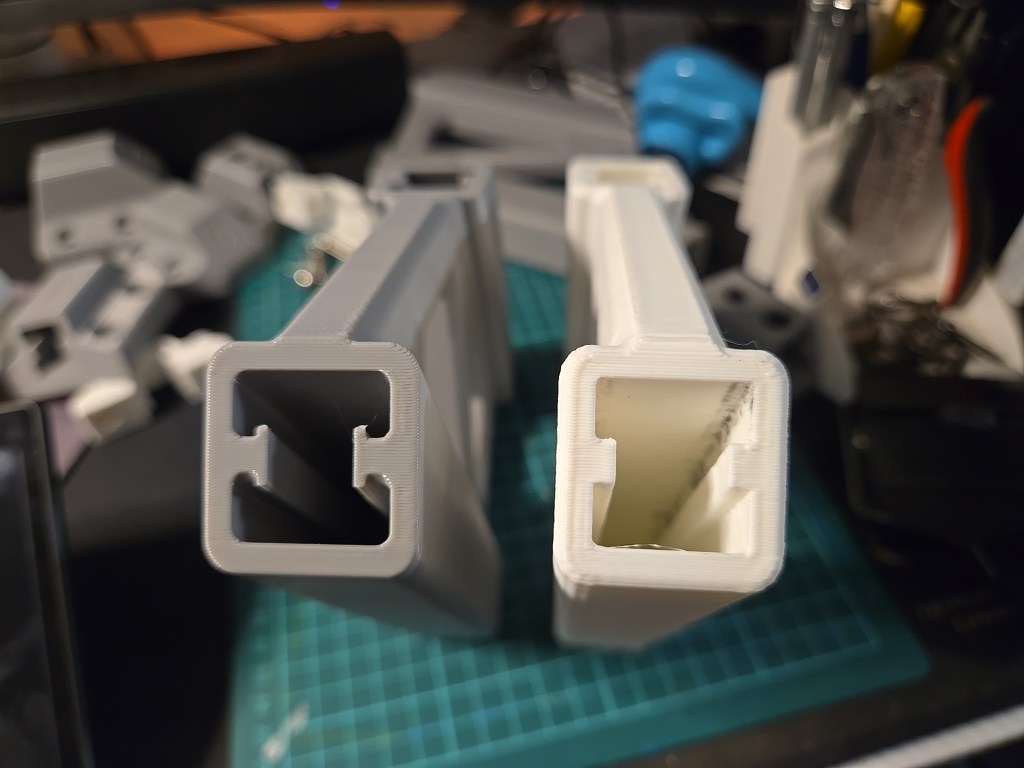

The image below shows the changes but in summary, I increased the side clearances to reduce/eliminate wall friction, strengthened the slider ribs and added a flange to help retain grease if added, and increased corner fillets (rounding) to reduce/eliminate stress concentrations:

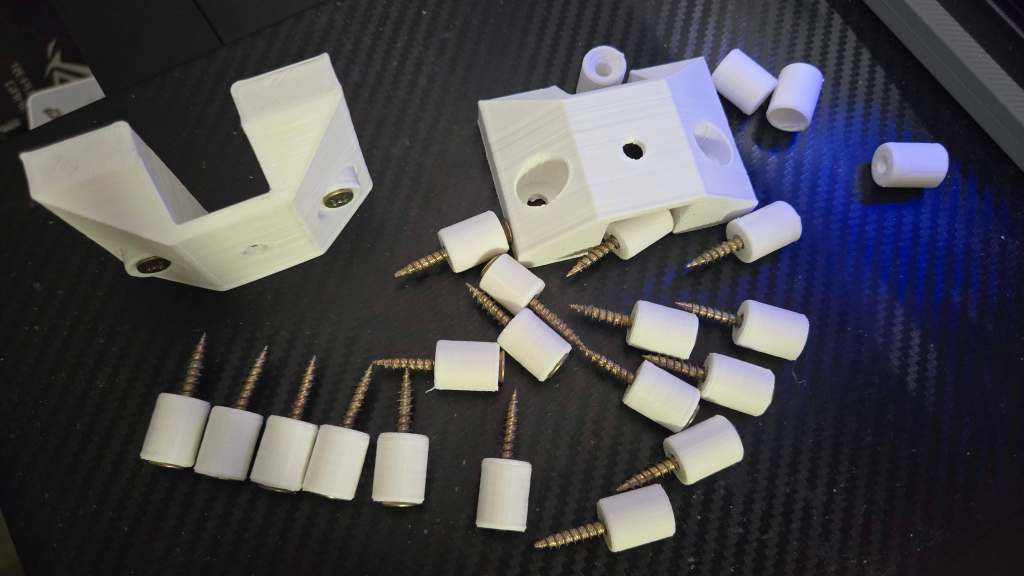

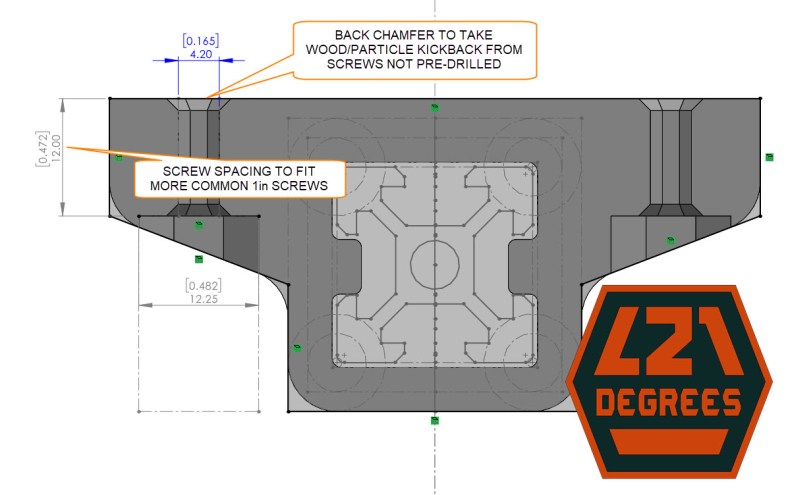

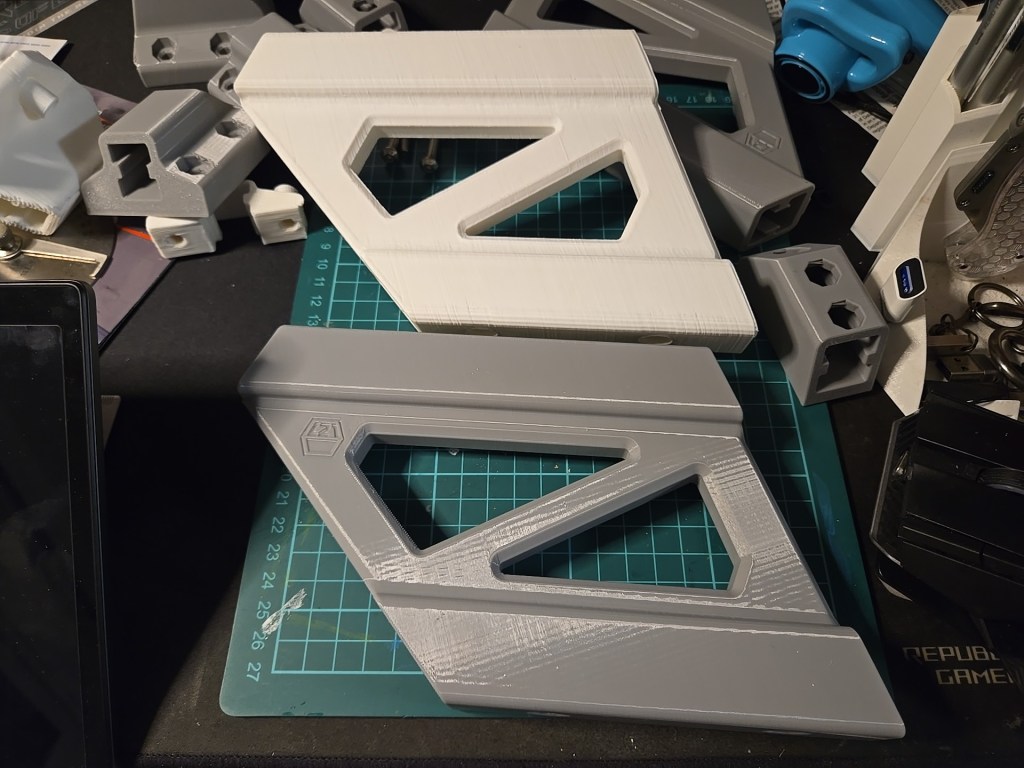

For the screw mounting, the shortest screw length I found at the hardware store was 1″ so I adjusted the mount spacing to take 1/2″ so they would thread 1/2″ into my 3/4″ desktop. Also, I didn’t pre-drill holes for them so some material would kick-back/lift out around the screw which separated the flat surface on the mounting brackets so I added chamfering around the mounting holes to help take it:

Available to download at MakerWorld: https://makerworld.com/en/models/878613

And recently uploaded to Printables: https://www.printables.com/model/1144913-keyboard-megashelf-sliding-keyboard-and-peripheral

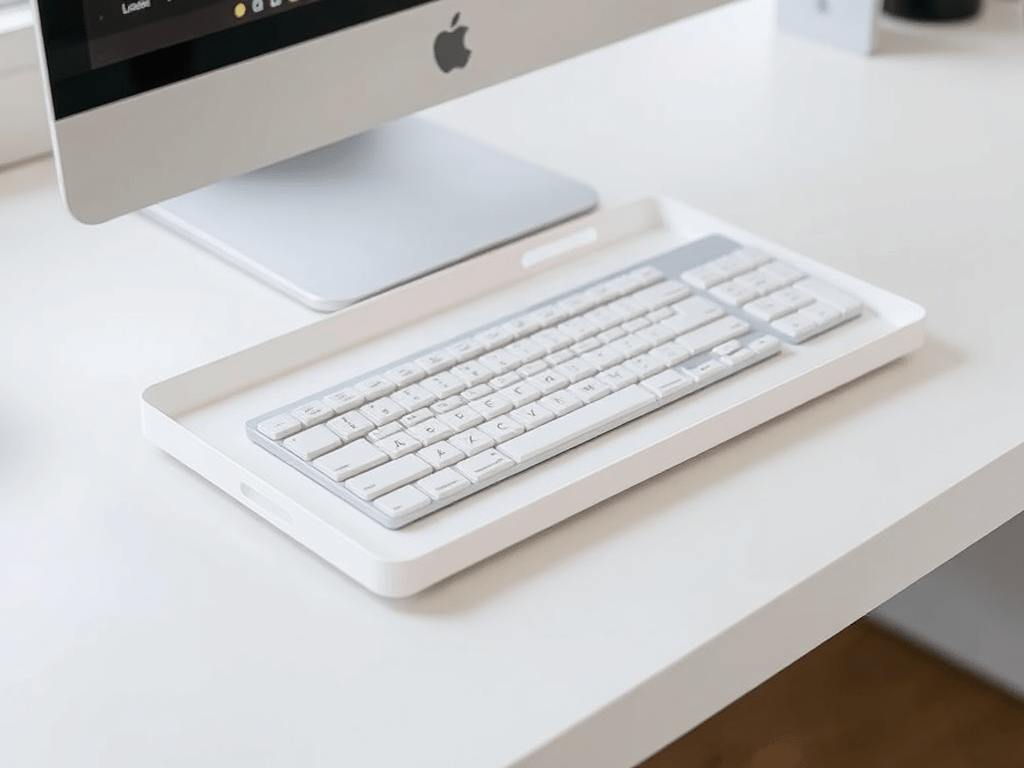

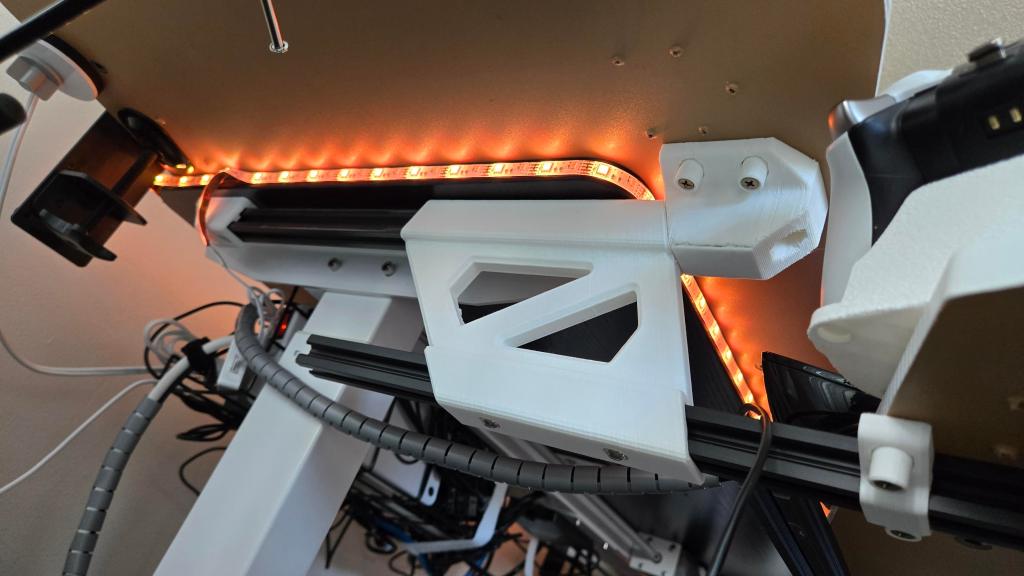

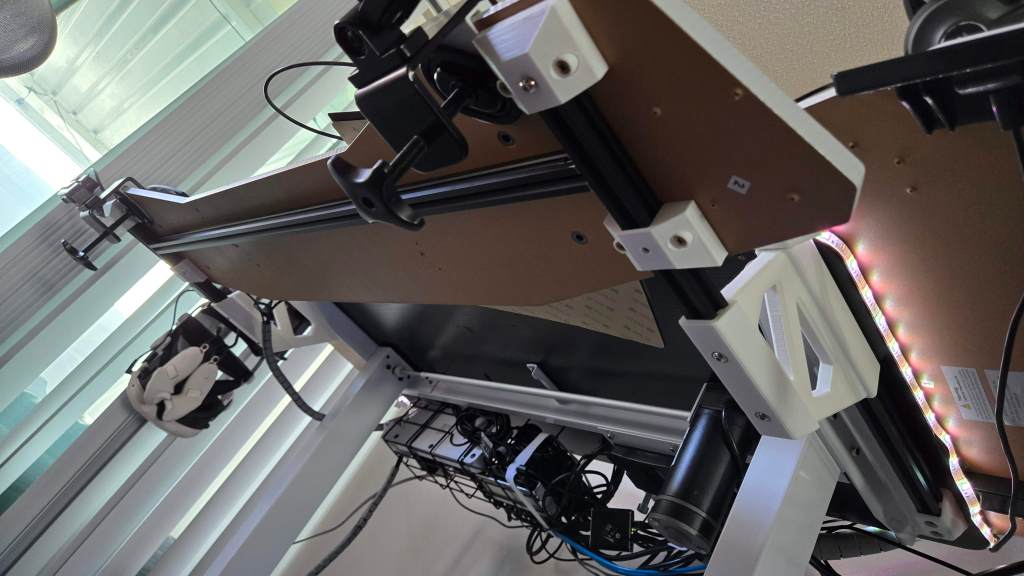

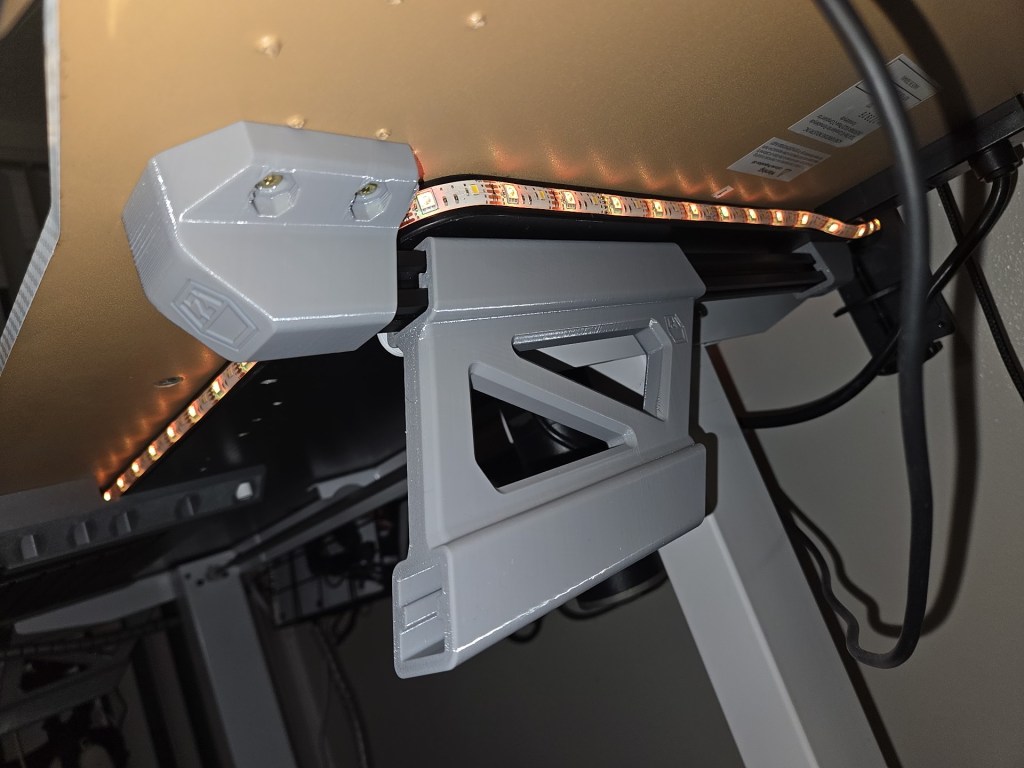

Here’s a gallery of the newly printed components:

*BONUS* AI generated images for keyboard trays: