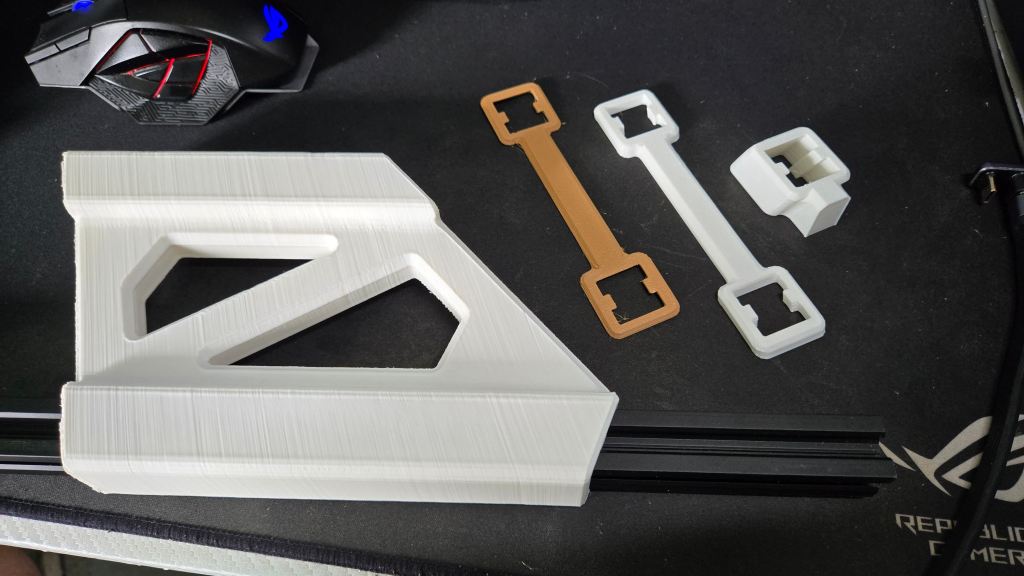

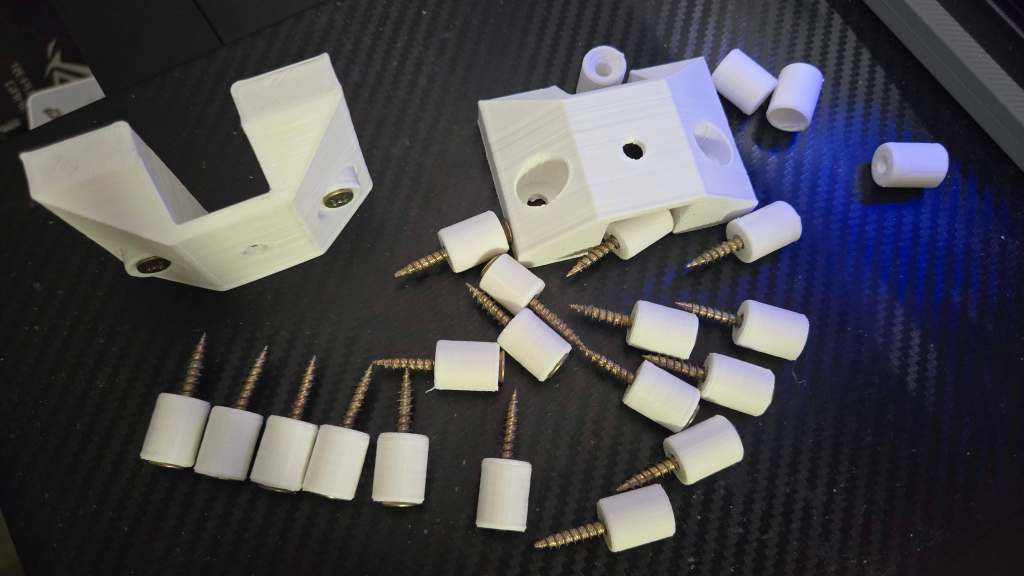

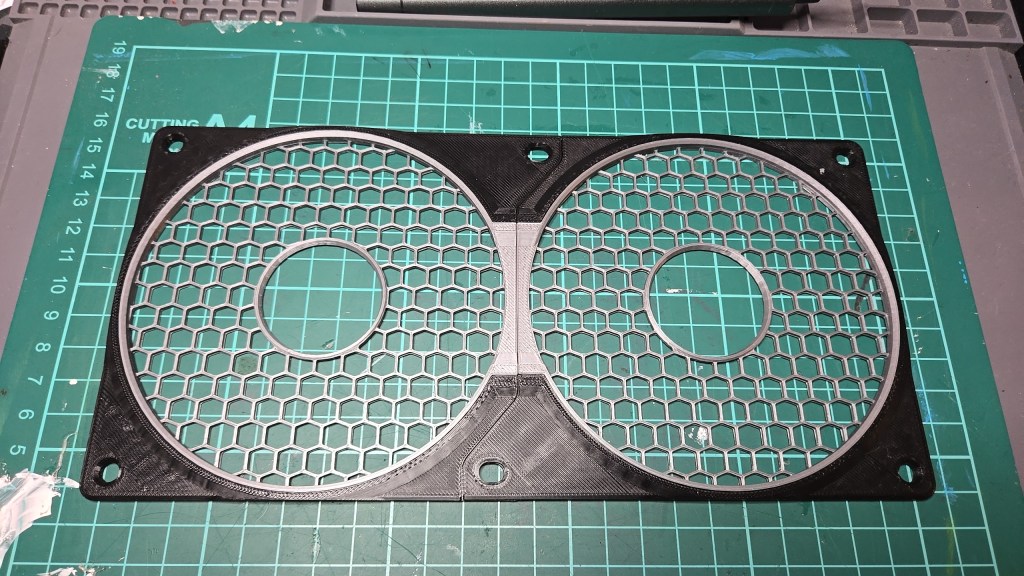

Print settings:

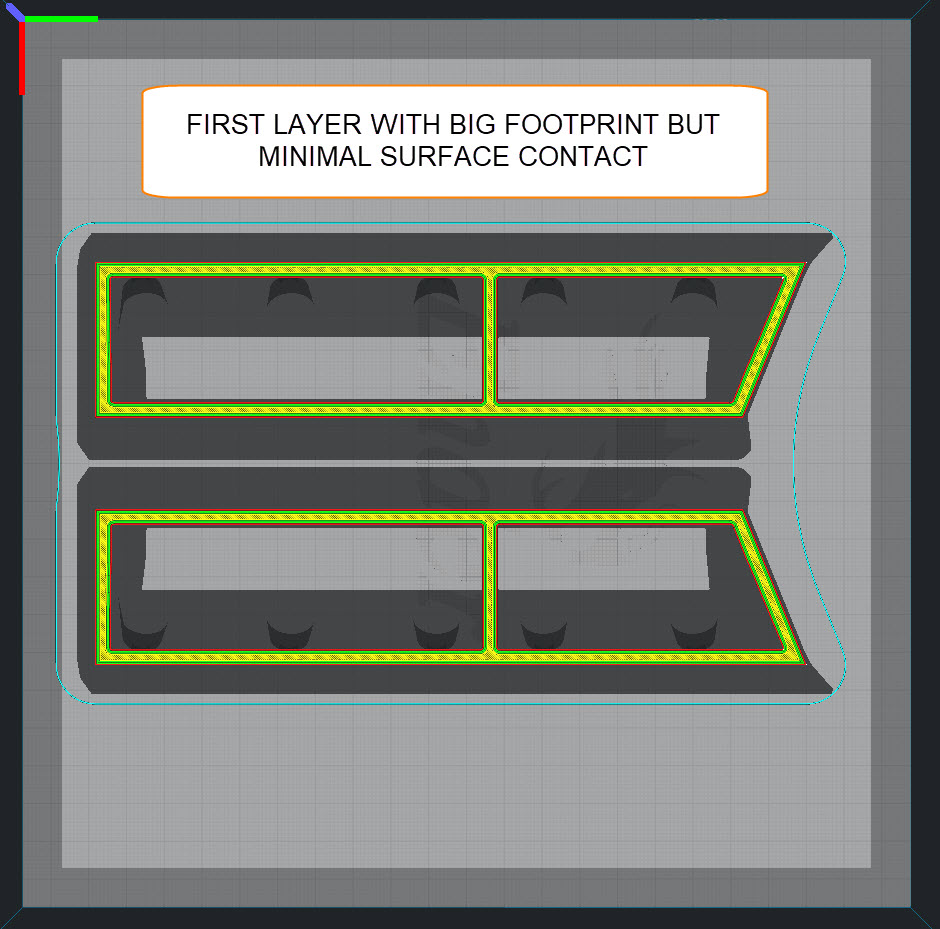

- Printer: Bambu Lab P1S

- Nozzle: 0.40mm

- Layer height: 0.20mm

- Filament: Bambu Lab green and orange PLA, 3D Solutech Silver Metal PLA

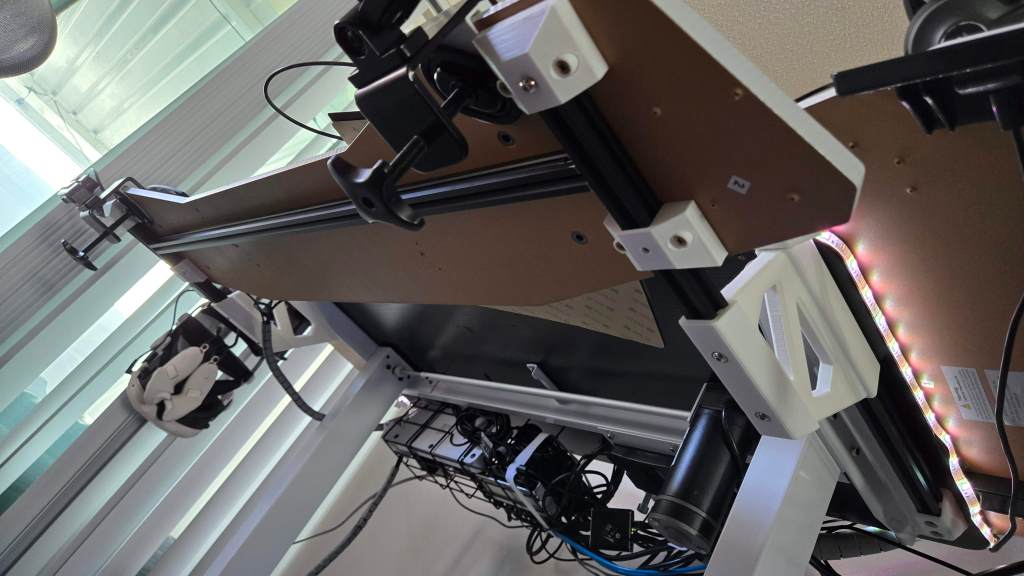

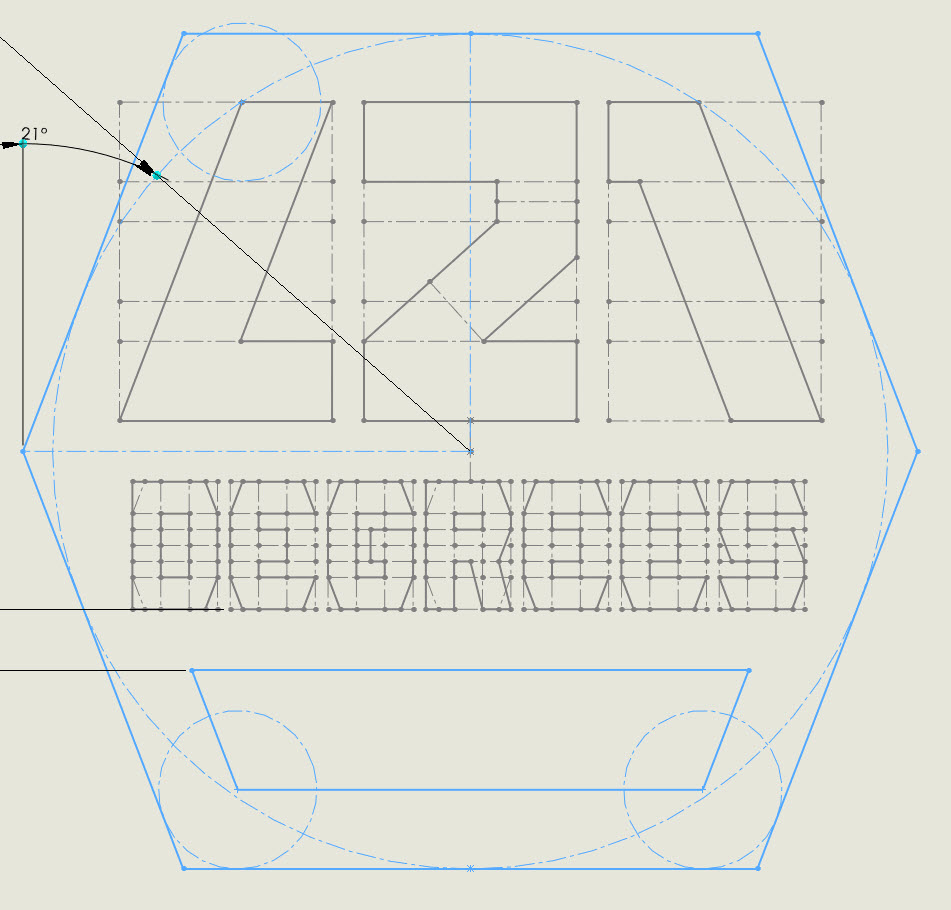

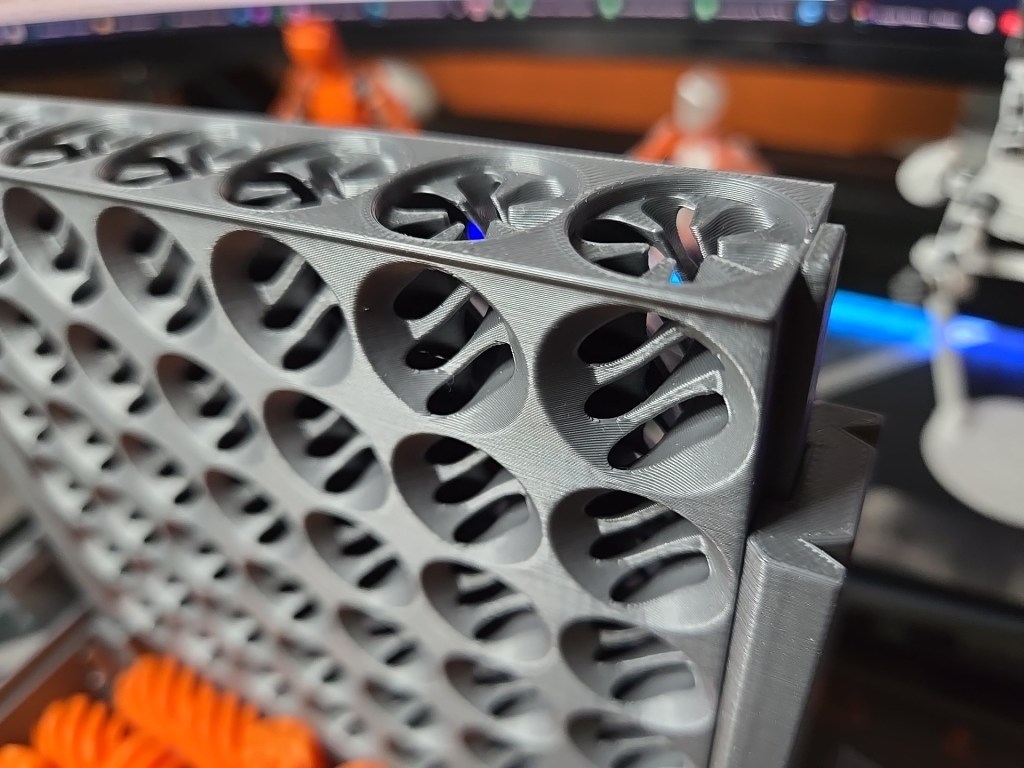

This is an awesome “spin” on this classic game, only reasonably possible with additive manufacturing. Every column is a spiral cut all the way from the top to bottom, the pieces are shaped as an offset of the spiral cuts which slide down slowly in a very satisfying drop.

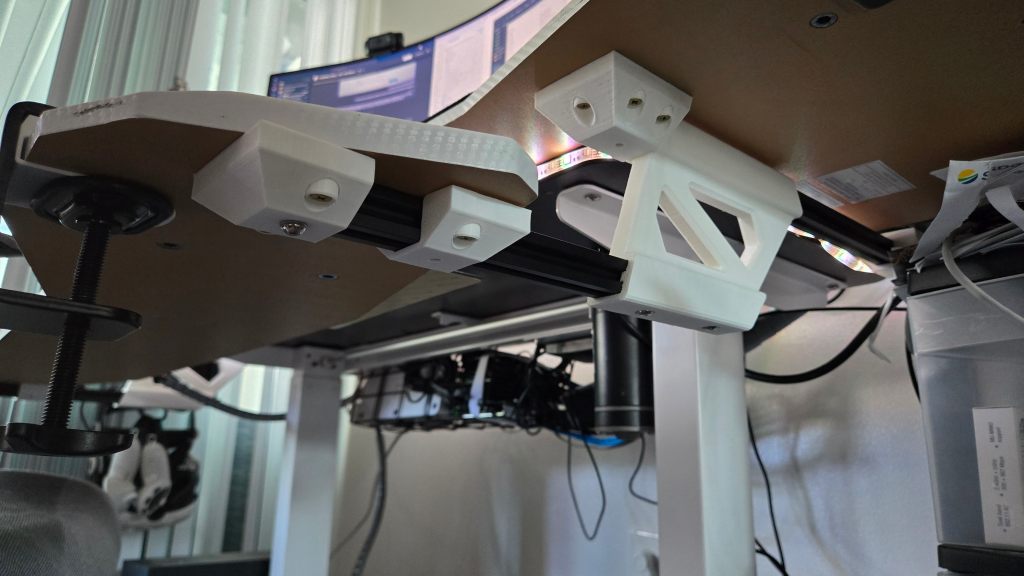

When the game ends, the game part can be lifted enough to allow one row of pieces to be exposed, the side clasps will retain it and then players can push the pieces to their respective side.

Another function of the clasps is to retain the game part as a cover to stow the whole thing away.

Designer/Uploader: @evets17, download: MakerWorld.